Versatile 3D Materials

Materials

Explore our range of FDM and SLA 3D printing materials. Whether you're going big with FDM or focusing on fine details with SLA, we've got you covered.

Printing Methods Blog

-

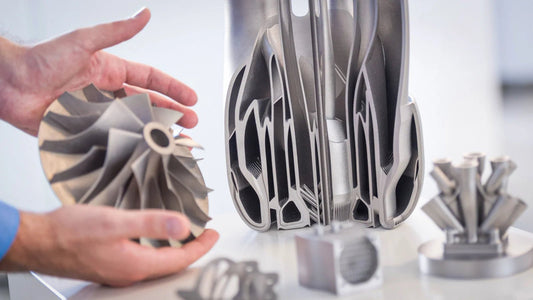

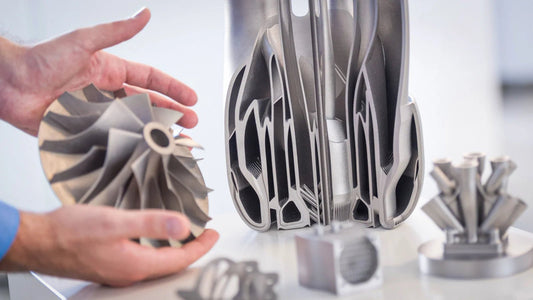

Exploring the Good and the Bad of Metal SLS Pri...

Metal Selective Laser Sintering (SLS) is one of the most advanced 3D printing technologies available today. It's a process that uses a laser to sinter powdered metal, binding the material...

Exploring the Good and the Bad of Metal SLS Pri...

Metal Selective Laser Sintering (SLS) is one of the most advanced 3D printing technologies available today. It's a process that uses a laser to sinter powdered metal, binding the material...

-

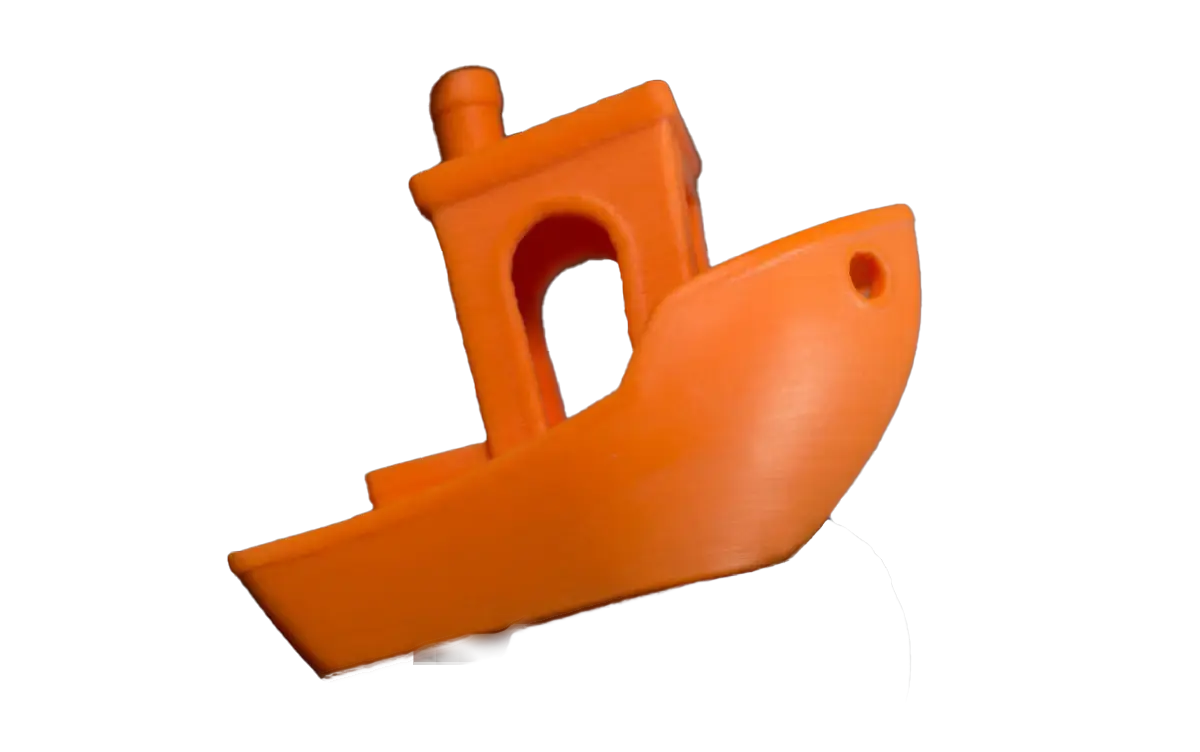

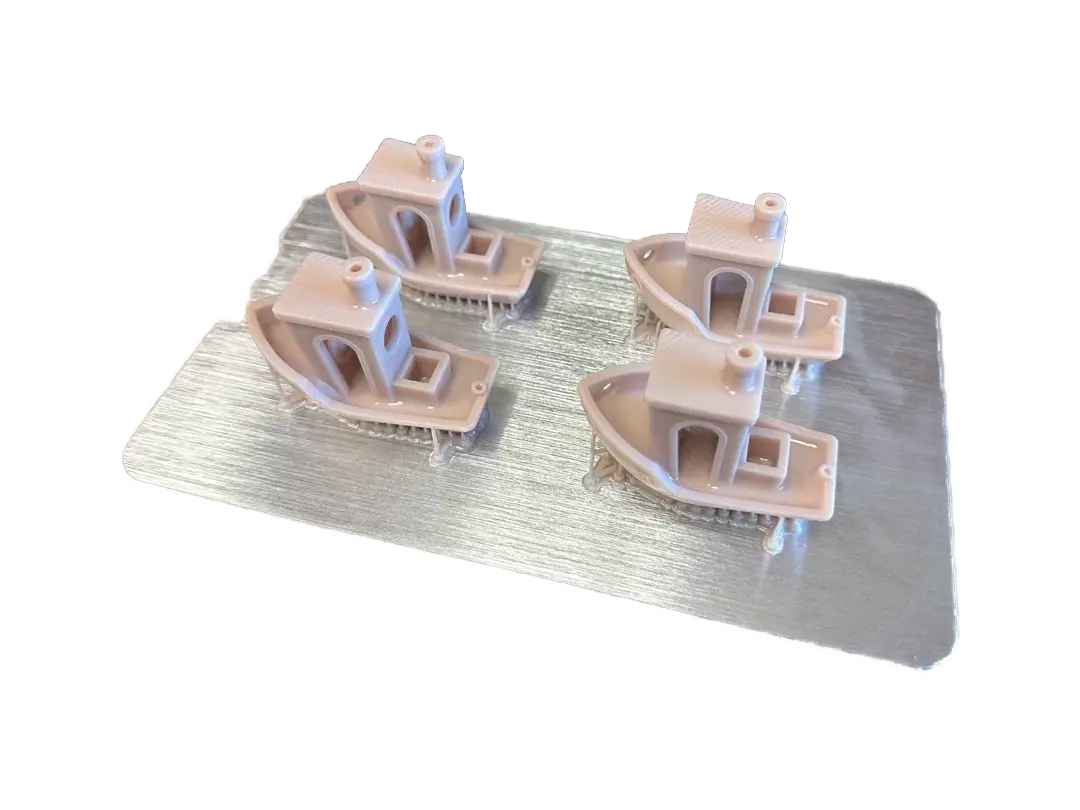

Exploring FDM 3D Printing and Its Uses

Introduction: Fused Deposition Modeling (FDM) is one of the most widely used 3D printing technologies, known for its affordability and versatility. In this blog, we'll dive into the basics of...

Exploring FDM 3D Printing and Its Uses

Introduction: Fused Deposition Modeling (FDM) is one of the most widely used 3D printing technologies, known for its affordability and versatility. In this blog, we'll dive into the basics of...

-

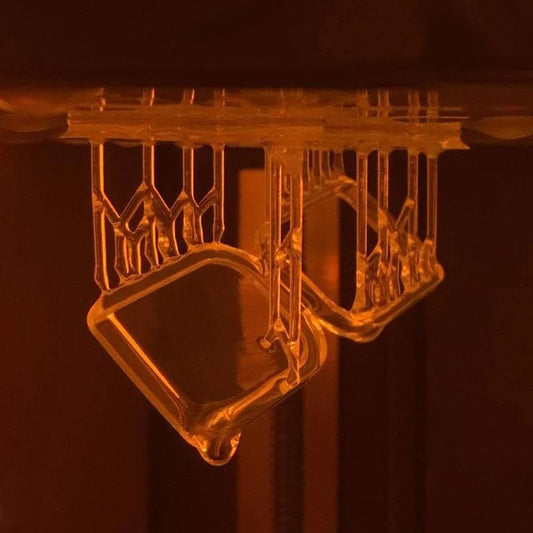

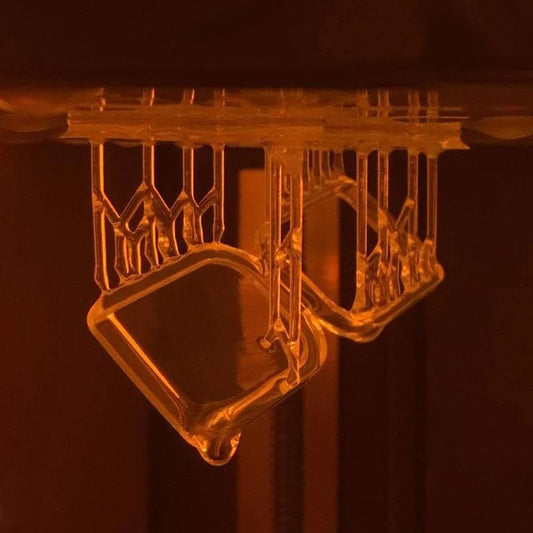

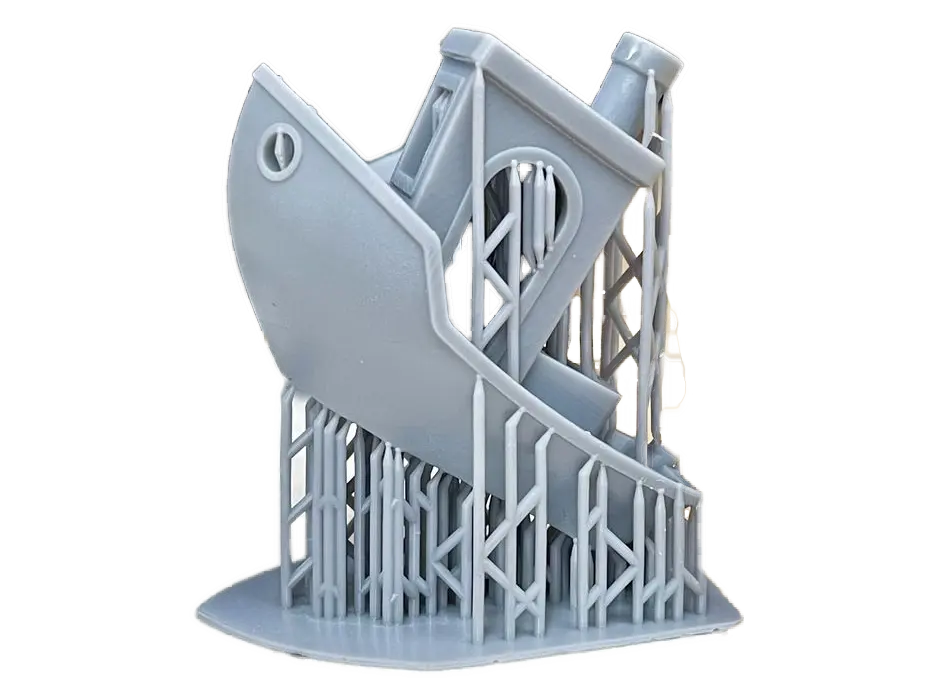

Understanding SLA 3D Printing and Its Uses. The...

ntroduction: Stereolithography (SLA) 3D printing is a game-changer in the world of additive manufacturing. Known for its high precision and smooth surface finishes, SLA is ideal for creating intricate designs...

Understanding SLA 3D Printing and Its Uses. The...

ntroduction: Stereolithography (SLA) 3D printing is a game-changer in the world of additive manufacturing. Known for its high precision and smooth surface finishes, SLA is ideal for creating intricate designs...

We have it all—below are our FDM material options.

Easy-to-use and eco-friendly

PLA (Polylactic Acid)

Is a biodegradable plastic made from renewable resources like corn starch. It's the go-to material for beginners due to its ease of use, low warping, and good surface finish. PLA is ideal for prototyping, decorative items, and non-functional models, though it is less durable and heat-resistant compared to other materials.

Strong and impact-resistant

ABS (Acrylonitrile Butadiene Styrene)

Is known for its toughness and impact resistance. Commonly used in automotive parts and toys, ABS requires higher printing temperatures and a heated bed to prevent warping. It offers superior durability, flexibility, and heat resistance, making it suitable for functional parts that need to withstand stress and temperature.

Versatile and durable

PETG (Polyethylene Terephthalate Glycol)

Combines the ease of PLA with the durability of ABS. It is resistant to chemicals and water, making it a versatile choice for functional parts that require impact resistance and environmental stability. PETG’s glossy finish and transparency are added benefits for certain applications.

Flexible and resilient

TPU (Thermoplastic Polyurethane)

Is a flexible, rubber-like material used for creating parts that require elasticity, such as gaskets, seals, and phone cases. It offers excellent abrasion resistance and shock absorption, though printing with TPU requires specialized equipment due to its flexibility.

Strong and wear-resistant

Nylon

Is a strong and flexible material with excellent wear and chemical resistance. It’s often used in industrial applications for parts that need to endure friction and impact, like gears and mechanical components. Nylon’s high tensile strength makes it ideal for durable and stress-resistant parts.

Lightweight and ultra-strong

Carbon Fiber

Are composites that blend carbon fibers with a base material like PLA, PETG, or Nylon. These filaments are lightweight, strong, and offer high dimensional stability, making them ideal for applications in aerospace, automotive, and sports equipment. However, they are more abrasive on printer nozzles, requiring hardened steel nozzles for printing.

Safe for food contact

Food-Safe FDM Materials

Food-safe filaments are specially formulated to be safe for items that come into contact with food. Common food-safe filaments include certain grades of PLA, PETG, and Nylon. These materials are used to create items like kitchen utensils, food containers, and other objects where safety and hygiene are a priority. It’s important to verify that the filament is certified food-safe by the manufacturer and to consider post-processing techniques, like sealing or coating, to ensure the printed item remains food-safe.

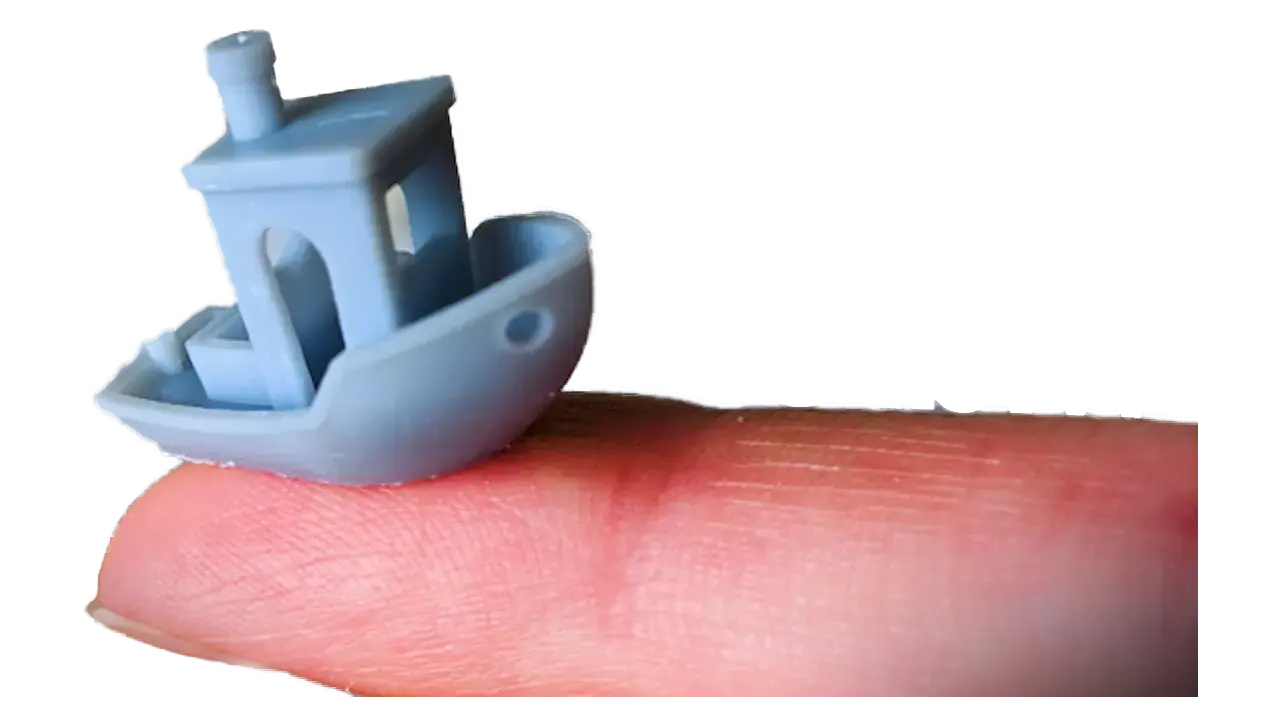

We have it all—below are our SLA material options.

Versatile and reliable

Standard Resins

Standard resins are the go-to choice for high-resolution prints with smooth surfaces. Ideal for prototypes, visual models, and general-purpose use, these resins offer a balance of performance and cost-effectiveness, making them a popular choice for a wide range of applications.

Durable and impact-resistant.

Tough Resins

Tough resins are engineered to simulate the strength and durability of ABS plastic. Perfect for functional prototypes and parts that need to endure mechanical stress, these resins are ideal for creating robust, durable models ready for rigorous testing and use.

Elastic and versatile

Flexible Resins

Flexible resins offer the elasticity needed for parts that must bend, compress, or stretch. Commonly used in wearables, custom grips, and gaskets, these resins balance flexibility with strength, providing versatile solutions for dynamic applications.

Exceptional clarity and gloss

Transparent Glossy Resins

Transparent glossy resins are perfect for creating clear, high-gloss prints that demand attention. Ideal for applications like lenses, light guides, and display models, these resins deliver both aesthetic appeal and functional transparency.

Precision casting made easy.

Castable Resins

Castable resins are designed for investment casting, burning out cleanly to leave behind precise molds. Ideal for jewelry making and dental applications, these resins ensure that your metal castings are accurate and detailed, with no residue left behind.

Safe and biocompatible

Dental and Medical Resins

Dental and medical resins are specifically formulated for biocompatibility, making them safe for patient-specific applications. Used for dental models, surgical guides, and custom medical devices, these resins meet strict regulatory standards, ensuring safety and reliability.

Heat-resistant and strong

High-Temperature Resins

High-temperature resins are capable of withstanding extreme heat, making them ideal for applications like mold-making and functional prototypes that require thermal stability. These resins maintain their shape and strength even under high temperatures.

Stone-like finish and strength

Ceramic-Filled Resins

Ceramic-filled resins combine the properties of resin and ceramic to produce parts with a unique stone-like finish and enhanced mechanical strength. Ideal for applications requiring stiffness and heat resistance, these resins deliver both functionality and aesthetic appeal.