The Power of 3D Printing for Prototyping: Transforming Ideas into Reality

Share

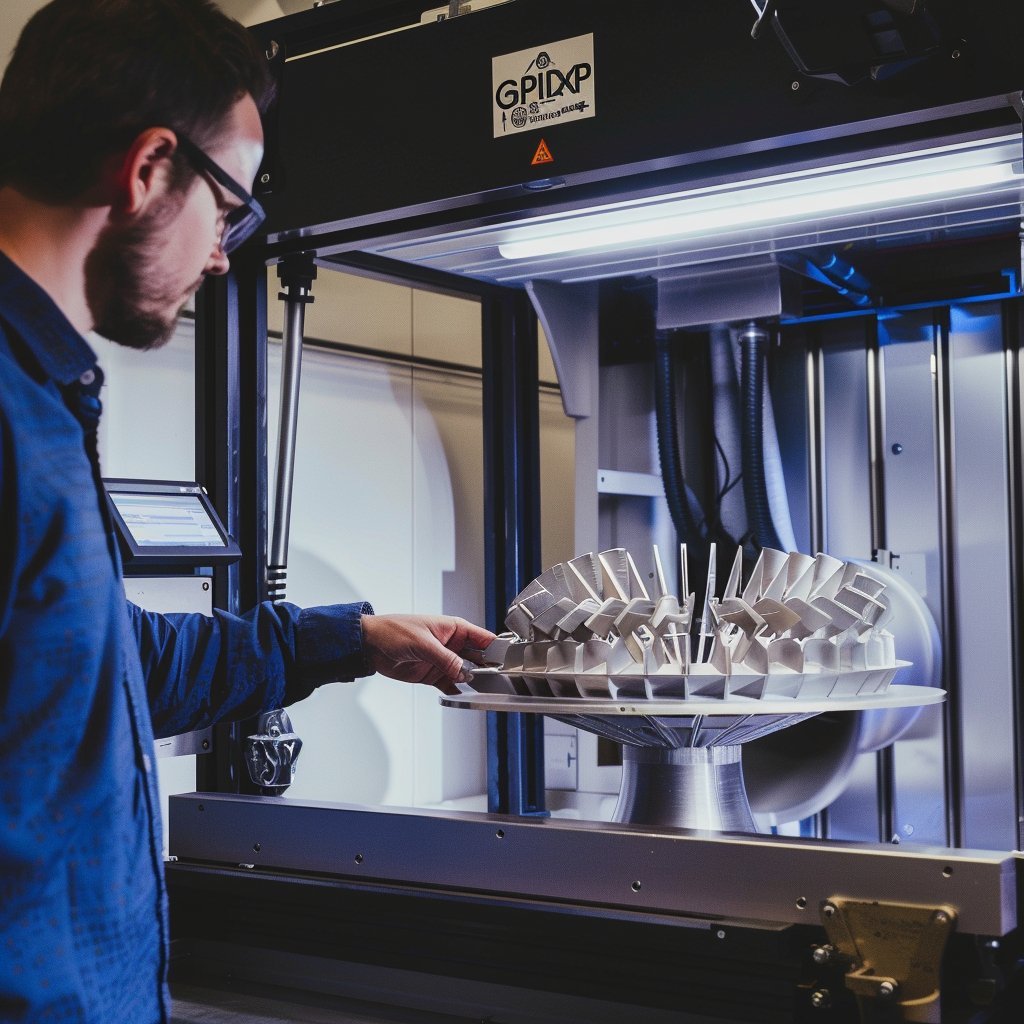

3D printing has become a game-changer in the world of prototyping, offering unparalleled ease, accuracy, and speed. Whether you are a student working on your master’s project or an entrepreneur developing a new product, 3D printing provides the tools you need to bring your ideas to life.

Benefits of 3D Printing in Prototyping

1. Speed and Efficiency:

• Traditional prototyping methods can take weeks or even months. With 3D printing, you can produce a prototype within hours, allowing for rapid iteration and refinement.

2. Accuracy and Detail:

• 3D printers can create highly detailed and precise models, ensuring that your prototype accurately reflects your design. This precision is crucial for functional testing and further development.

3. Cost-Effective:

• Traditional manufacturing processes often require expensive molds and tooling. 3D printing eliminates these costs, making it an affordable option for small-scale production and one-off prototypes.

4. Flexibility in Design:

• 3D printing allows for complex geometries and intricate details that are difficult or impossible to achieve with traditional methods. This flexibility opens up new possibilities for innovative designs.

5. Material Variety:

• Modern 3D printers can use a wide range of materials, including plastics, metals, and composites. This versatility enables you to choose the best material for your prototype based on its intended use and required properties.

Applications in Various Fields

1. Academic Projects:

• Students can use 3D printing to create detailed models and functional prototypes for their research and projects, enhancing their understanding and showcasing their work effectively.

2. Product Development:

• Entrepreneurs and businesses can quickly test and iterate on product designs, reducing the time to market and increasing the likelihood of success.

3. Engineering and Design:

• Engineers and designers can use 3D printing to visualize complex parts and assemblies, identify potential issues early, and make necessary adjustments before committing to full-scale production.

4. Healthcare and Medical Devices:

• 3D printing is used to create custom medical devices, prosthetics, and anatomical models, improving patient outcomes and enabling personalized treatment.

Challenges and Considerations

1. Material Limitations:

• While 3D printing offers a wide range of materials, not all are suitable for every application. It’s important to select the right material for your specific needs.

2. Design for 3D Printing:

• Successful 3D printing requires designs optimized for the technology. This may involve learning new software or adjusting existing designs to ensure printability.

3. Post-Processing:

• Depending on the material and desired finish, post-processing such as sanding, painting, or additional curing may be required.

Conclusion

3D printing has revolutionized prototyping, making it faster, more affordable, and more accessible than ever before. At Technast, we specialize in turning your ideas into tangible prototypes, whether for academic projects, product development, or engineering designs. With our state-of-the-art 3D printers and expertise, we ensure that your prototypes are of the highest quality and meet your specific requirements.

Ready to bring your ideas to life? Contact us today to discuss your project and see how 3D printing can help you achieve your goals.

Excerpt

Explore how 3D printing is transforming prototyping with speed, accuracy, and cost-efficiency. Whether you’re a student or a startup, learn how this technology can bring your ideas to life.

Feel free to adjust any part of the content to better fit your style or specific requirements!

Benefits of 3D Printing in Prototyping

1. Speed and Efficiency:

• Traditional prototyping methods can take weeks or even months. With 3D printing, you can produce a prototype within hours, allowing for rapid iteration and refinement.

2. Accuracy and Detail:

• 3D printers can create highly detailed and precise models, ensuring that your prototype accurately reflects your design. This precision is crucial for functional testing and further development.

3. Cost-Effective:

• Traditional manufacturing processes often require expensive molds and tooling. 3D printing eliminates these costs, making it an affordable option for small-scale production and one-off prototypes.

4. Flexibility in Design:

• 3D printing allows for complex geometries and intricate details that are difficult or impossible to achieve with traditional methods. This flexibility opens up new possibilities for innovative designs.

5. Material Variety:

• Modern 3D printers can use a wide range of materials, including plastics, metals, and composites. This versatility enables you to choose the best material for your prototype based on its intended use and required properties.

Applications in Various Fields

1. Academic Projects:

• Students can use 3D printing to create detailed models and functional prototypes for their research and projects, enhancing their understanding and showcasing their work effectively.

2. Product Development:

• Entrepreneurs and businesses can quickly test and iterate on product designs, reducing the time to market and increasing the likelihood of success.

3. Engineering and Design:

• Engineers and designers can use 3D printing to visualize complex parts and assemblies, identify potential issues early, and make necessary adjustments before committing to full-scale production.

4. Healthcare and Medical Devices:

• 3D printing is used to create custom medical devices, prosthetics, and anatomical models, improving patient outcomes and enabling personalized treatment.

Challenges and Considerations

1. Material Limitations:

• While 3D printing offers a wide range of materials, not all are suitable for every application. It’s important to select the right material for your specific needs.

2. Design for 3D Printing:

• Successful 3D printing requires designs optimized for the technology. This may involve learning new software or adjusting existing designs to ensure printability.

3. Post-Processing:

• Depending on the material and desired finish, post-processing such as sanding, painting, or additional curing may be required.

Conclusion

3D printing has revolutionized prototyping, making it faster, more affordable, and more accessible than ever before. At Technast, we specialize in turning your ideas into tangible prototypes, whether for academic projects, product development, or engineering designs. With our state-of-the-art 3D printers and expertise, we ensure that your prototypes are of the highest quality and meet your specific requirements.

Ready to bring your ideas to life? Contact us today to discuss your project and see how 3D printing can help you achieve your goals.

Excerpt

Explore how 3D printing is transforming prototyping with speed, accuracy, and cost-efficiency. Whether you’re a student or a startup, learn how this technology can bring your ideas to life.

Feel free to adjust any part of the content to better fit your style or specific requirements!