Rescuing Our Customer with Custom 3D-Printed Replacement Gears

Share

At Technast, we’re dedicated to finding innovative solutions to real-world problems with the power of 3D scanningand custom 3D printing. Recently, we helped a customer facing a difficult situation—20 broken gear pieces that were impossible to replace, leaving their equipment inoperable. In this success story, we’ll explore how we used high-precision 3D scanning, redesign, and 3D printing to create custom replacement gears and get our customer back on track.

The Challenge: Unavailable Replacement Parts

Our customer came to us with a broken gear, split in half, and urgently needed replacements. With 20 of these broken pieces and no viable replacement parts on the market, they faced the risk of long downtime and high costs. That’s where Technast stepped in to provide a cost-effective, rapid solution through 3D scanning and custom printing.

Step 1: Scanning the Broken Gear

The first step was to scan the broken part accurately to capture every detail, ensuring our replacement gears would be a perfect fit. Using our high-accuracy Mini2 Scanner, we scanned both halves of the broken gear. This technology enabled us to capture fine details of the original structure, providing the foundation for a precise digital model.

Step 2: Redesigning the Gear

Once we had the scanned data, our team of designers went to work reconstructing the gear. With 3D design software, we re-engineered the model to create a solid, seamless version that matched the exact specifications of the original. This step was critical, as even slight discrepancies in the design could impact performance.

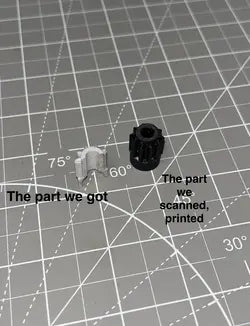

Step 3: Printing Custom Replacement Gears

After finalizing the design, we moved on to 3D printing the new gears. We used durable materials to ensure that these replacements would withstand the demands of daily use. The results were impressive, with each printed gear maintaining the necessary accuracy, strength, and durability required by the customer’s equipment.

The finished parts were tested to ensure functionality, and they fit perfectly within the machinery. The customer was thrilled to see their equipment back in action without the long wait or expense of sourcing rare replacement parts.

Why Choose Technast for Replacement Parts

This success story highlights Technast’s ability to provide high-quality, custom 3D printing solutions in situations where traditional replacement parts are unavailable. By combining 3D scanning, design expertise, and advanced 3D printing technology, we’re able to deliver fast, reliable, and cost-effective solutions for our clients’ toughest challenges.

Bringing Your Ideas to Life with Technast

Whether you need a replacement part, a prototype, or a custom design, Technast has the tools and expertise to make it happen. We specialize in high-precision scanning and printing to create parts that meet the unique needs of each project. If you’re looking for an innovative way to solve a part replacement challenge, reach out to Technast today.