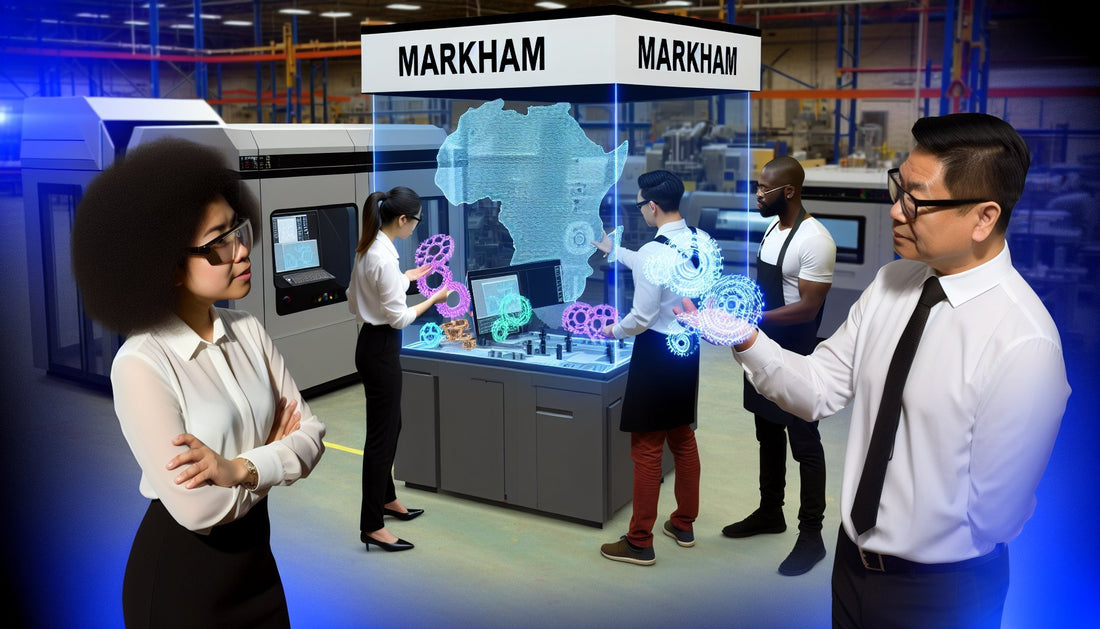

This blog explores how 3D printing and CAD design are transforming local manufacturing in Markham, Ontario, highlighting the benefits, sustainability practices, and collaborative efforts propelling innovation in the industry.

Share

Markham, Ontario, has emerged as a hotspot for technological innovation in Canada, especially within the realms of 3D printing, CAD design, and engineering solutions. As industries increasingly adopt these advanced technologies, local manufacturers are transforming their operations, increasing efficiencies, and enhancing sustainability efforts. This blog post explores how innovations in 3D printing and CAD design are radically reshaping the landscape of local manufacturing in Markham, providing valuable insights into the trends and benefits driving this evolution.

### The Growing Influence of 3D Printing in Manufacturing

3D printing, often referred to as additive manufacturing, is poised to revolutionize how products are conceived, designed, and produced. According to a report by Statista, the global 3D printing market is expected to reach approximately USD 44.4 billion by 2028, owing to increasing industrial demand for faster production and customized items. In Markham, manufacturing firms are rapidly integrating 3D printing technologies into their workflows to enhance prototype development and product customization.

Local businesses leveraging 3D printing enjoy remarkable advantages, including reduced material waste and quicker turnaround times. A case in point is the automotive industry, where companies in Markham are utilizing 3D printing to produce lightweight components and prototype designs efficiently, enhancing performance while minimizing costs. Research from the *Harvard Business Review* suggests that organizations adopting 3D printing technologies can decrease production time by as much as 75%, which is crucial in today's fast-paced market.

### The Role of CAD Design in Engineering Solutions

As 3D printing continues to gain traction, the importance of computer-aided design (CAD) becomes even more pronounced. CAD technologies empower engineers and designers in Markham to craft intricate 3D models that can be easily manipulated, tested, and optimized. The integration of CAD design with 3D printing offers a streamlined approach to manufacturing—one where mistakes are minimized, and corrections can be implemented seamlessly.

According to a study by the *International Journal of Advanced Manufacturing Technology*, companies using CAD saw a productivity increase of 25% to 50%. This efficiency translates into significant time savings when transitioning from design to manufacturing. In Markham, the presence of educational institutions such as York University ensures that the workforce is well-informed about CAD advancements and their application within local industries.

### Sustainability Through Innovation

The manufacturing sector faces ever-increasing pressure to adopt sustainable practices, and Markham's local manufacturers are rising to the challenge. The utilization of 3D printing and CAD design not only boosts efficiency but also contributes to reducing the carbon footprint of manufacturing operations. Research indicates that additive manufacturing can lower material waste by 90% compared to traditional methods (Source: World Economic Forum).

In Markham, many organizations are exploring eco-friendly materials and manufacturing processes. For example, businesses are investing in biodegradable materials and energy-efficient production strategies. This focus on sustainability not only addresses consumer demands for more responsible products but also enhances brand reputation in a competitive marketplace.

### Collaboration and Knowledge Sharing

A thriving ecosystem for manufacturing innovation in Markham is fostered through collaboration between businesses, educational institutions, and industry stakeholders. Local initiatives, such as the Markham Board of Trade and the Markham Innovation Centre, encourage knowledge sharing and resource accessibility, enabling small and medium-sized enterprises (SMEs) to adopt new technologies.

Additionally, universities and colleges in Markham provide training programs that equip students with the skills necessary for advanced manufacturing careers. This local emphasis on education ensures that upcoming generations of engineers and designers are well-prepared to harness the full potential of 3D printing and CAD technologies in their future careers.

### Conclusion

The future of local manufacturing in Markham, Ontario, is being shaped by substantial innovations in 3D printing and CAD design. These technologies not only facilitate quicker and more efficient product development but also promote sustainable practices that resonate with today’s environmentally-conscious consumers. As Markham continues to foster a collaborative ecosystem for innovation, businesses will find themselves at the forefront of advancements that will define the next era of manufacturing.

At Technast, we are committed to providing our readers with the latest insights into advancements in engineering solutions and local manufacturing in Markham. Stay tuned for further developments as we continue exploring the fascinating world of 3D printing and its impact on industry.

Featured Image URL: