Revolutionizing Design with CFD

Share

Computational Fluid Dynamics at the Forefront of Innovation

Introduction

In the rapidly advancing field of engineering, Computational Fluid Dynamics (CFD) has emerged as a pivotal technology, enabling designers and engineers at Technast to simulate fluid behavior in a virtual environment. This blog post delves into the power of CFD, illustrating how it is employed to solve complex fluid interaction problems across various industries, from aerospace to renewable energy.

What is Computational Fluid Dynamics (CFD)?

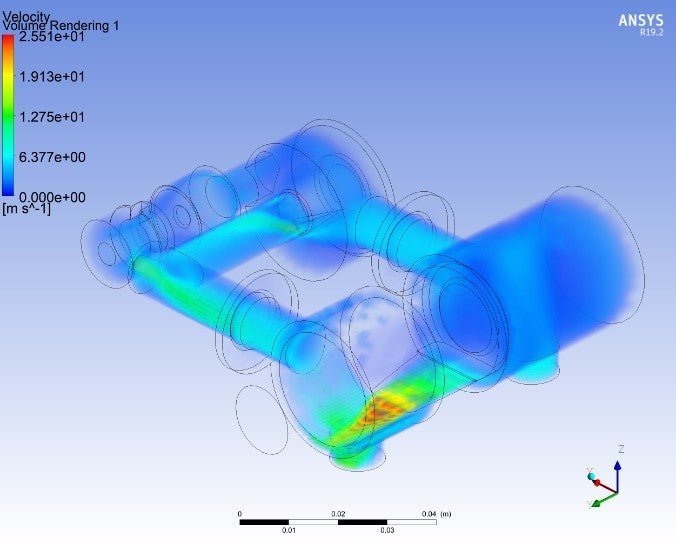

Computational Fluid Dynamics (CFD) is a branch of fluid mechanics that uses numerical analysis and data structures to solve and analyze problems involving fluid flows. By employing algorithms and computational resources, CFD allows engineers to visualize and predict the behavior of fluid systems under various conditions without physical prototypes.

Advanced CFD Techniques and Tools

At Technast, we utilize cutting-edge CFD tools and techniques to enhance our designs:

-

High-Performance Computing (HPC): Leveraging the power of HPC, we conduct complex simulations that require massive computational resources to ensure accuracy and efficiency in our fluid dynamics studies.

-

Multi-phase Flow Modeling: We model interactions between different fluid phases—such as liquids, gases, and particulates—to optimize designs for systems like automotive engines, chemical reactors, and environmental controls.

-

Real-Time Simulation and Visualization: Using state-of-the-art software, we provide real-time feedback and detailed visualizations of fluid dynamics, enabling immediate adjustments and optimization of designs.

Applications of CFD in High-Tech Engineering

CFD's versatility makes it indispensable in several high-tech engineering applications:

- Aerospace: Designing more efficient aircraft by optimizing airflow over wings and through jet engines to enhance performance and reduce fuel consumption.

- Automotive: Improving the aerodynamics of vehicles for better fuel efficiency and safety, and designing advanced cooling systems to manage engine heat.

- Energy: Enhancing the efficiency of turbines in wind farms and optimizing flow in hydroelectric systems to maximize power generation.

- Environmental Engineering: Simulating pollutant dispersion and water treatment processes to aid in environmental protection and sustainability initiatives.

Integrating CFD into the Design Process

Integrating CFD into our design process at Technast allows us to:

- Predict and solve complex fluid-related issues before physical testing, reducing development costs and time.

- Enhance product performance and safety by understanding fluid behavior in realistic scenarios.

- Innovate with confidence, pushing the boundaries of traditional design to explore new solutions and applications.

Conclusion

CFD is more than just a simulation tool at Technast—it is a gateway to innovation and precision in engineering. By harnessing the sophisticated capabilities of Computational Fluid Dynamics, we tackle some of the most challenging problems in fluid mechanics, leading to breakthroughs that reshape industries. Our commitment to advancing CFD technology ensures that we remain at the cutting edge of design and development.

Stay connected with our blog for more insights into how Technast is using advanced technologies like CFD to drive progress and innovation in engineering.