Thermal Management Solutions

Share

Advanced Thermal Management Solutions for Efficient Heat Exchangers

As the demand for highly efficient thermal management solutions continues to rise, advancements in additive manufacturing (AM) have revolutionized the design and production of heat exchangers. Leveraging the power of 3D printing, engineers and manufacturers can now create highly optimized, intricate structures that significantly enhance thermal performance and efficiency.

The Power of Additive Manufacturing in Thermal Management

1. Customized Designs for Optimal Performance: Traditional manufacturing techniques often limit the complexity and customization of heat exchangers. Additive manufacturing, however, allows for the creation of intricate geometries tailored to specific thermal management needs. By utilizing AM, engineers can design and produce heat exchangers with optimized fluid flow paths and enhanced heat transfer capabilities, resulting in superior performance.

2. Enhanced Efficiency with Lightweight Structures: One of the key advantages of 3D printing is the ability to create lightweight structures without compromising strength and durability. Lightweight heat exchangers not only improve thermal efficiency but also reduce material usage and overall system weight. This is particularly beneficial in industries such as aerospace and automotive, where weight reduction is critical for improving fuel efficiency and performance.

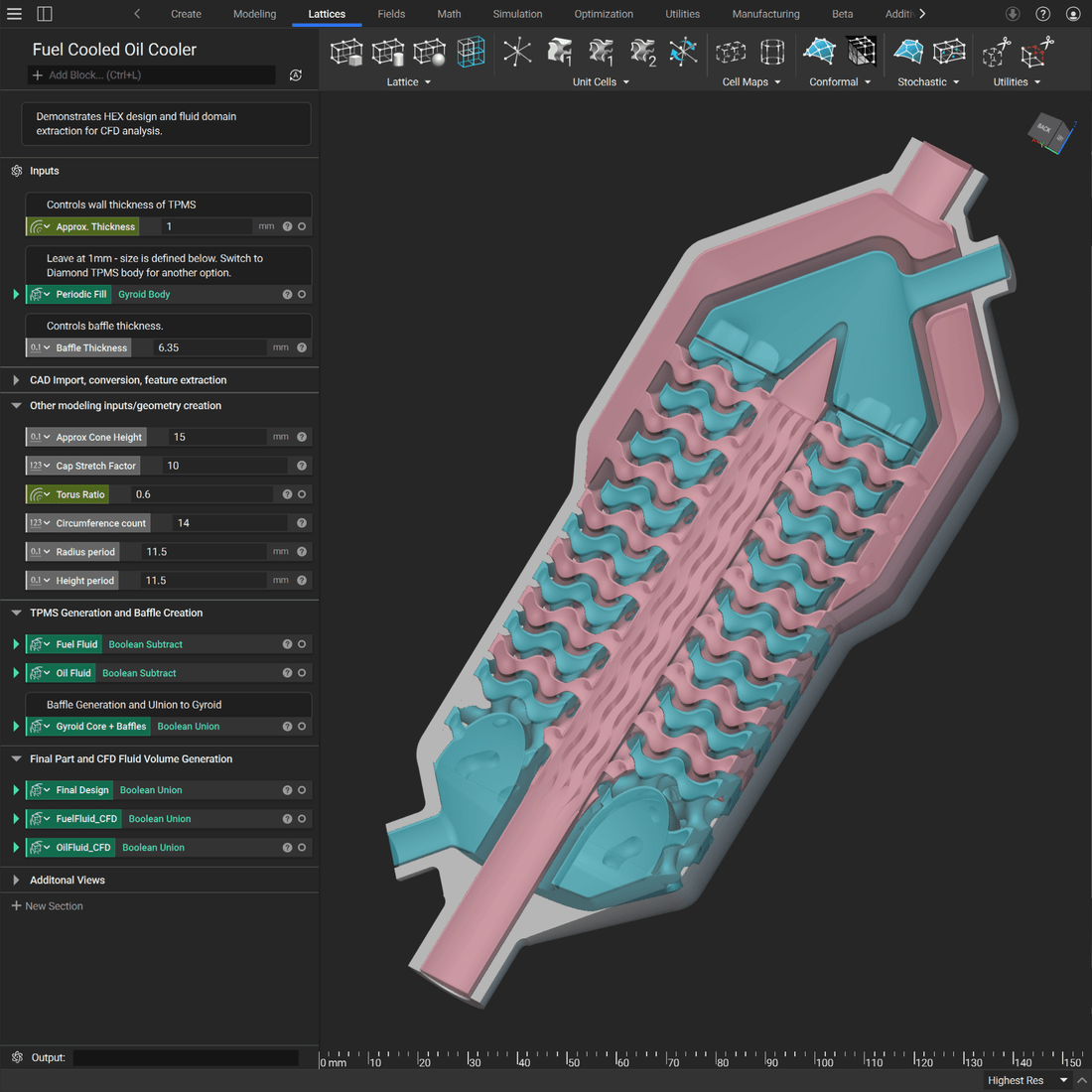

3. Complex Lattice Structures for Superior Heat Dissipation: Additive manufacturing enables the production of complex lattice structures that enhance heat dissipation and thermal conductivity. These intricate designs provide a larger surface area for heat transfer, allowing for more efficient cooling and improved overall performance. The flexibility of AM also allows for the integration of multiple functionalities within a single heat exchanger, further optimizing thermal management.

4. Rapid Prototyping and Iterative Design: With 3D printing, the prototyping and design iteration process becomes significantly faster and more cost-effective. Engineers can quickly produce and test multiple iterations of heat exchanger designs, optimizing performance before final production. This agility in the design process allows for rapid innovation and the ability to meet evolving thermal management requirements.

Real-World Applications and Success Stories

1. Aerospace Industry: In the aerospace industry, where efficient thermal management is crucial for the performance and longevity of components, additive manufacturing has enabled the production of lightweight heat exchangers with complex internal structures. These advanced heat exchangers improve cooling efficiency in aircraft engines, reducing maintenance costs and enhancing overall performance.

2. Automotive Sector: The automotive sector has also embraced 3D printing for thermal management solutions. By utilizing additive manufacturing, automotive manufacturers can create custom heat exchangers that optimize cooling in electric vehicle (EV) batteries and power electronics. The result is improved thermal performance, increased battery life, and enhanced vehicle efficiency.

3. Electronics and Data Centers: In the electronics and data center industries, efficient thermal management is essential for preventing overheating and ensuring optimal performance. Additive manufacturing allows for the creation of heat exchangers with complex microchannel designs, enabling efficient heat dissipation in compact electronic devices and high-performance data centers.

Partnering with Technast for Cutting-Edge Thermal Management Solutions

At Technast, we specialize in leveraging the latest advancements in additive manufacturing to provide innovative thermal management solutions. Our team of experienced engineers and designers work closely with clients to develop customized heat exchangers that meet their specific requirements. From concept to production, we utilize state-of-the-art 3D printing technologies to deliver high-quality, efficient, and reliable thermal management solutions.

Conclusion

Additive manufacturing has revolutionized the field of thermal management, offering unprecedented design flexibility, enhanced efficiency, and rapid prototyping capabilities. By harnessing the power of 3D printing, industries can achieve superior thermal performance, reduce costs, and drive innovation. Partner with Technast to explore the endless possibilities of advanced thermal management solutions and take your heat exchanger designs to the next level.