Metamaterials

Share

Title: Enhancing Manufacturing with Metamaterials

Explore how metamaterials improve traditional manufacturing processes and open new design possibilities. Learn how these innovative materials enable the creation of structures with unique properties, revolutionizing various industries from aerospace to medical devices.

---

### Enhancing Manufacturing with Metamaterials

In the realm of advanced manufacturing, metamaterials are pushing the boundaries of what’s possible. These engineered materials, designed to have properties not found in naturally occurring substances, are transforming traditional manufacturing processes and unlocking new design possibilities. At Technast, we leverage the power of metamaterials to bring innovative solutions to our clients.

#### What are Metamaterials?

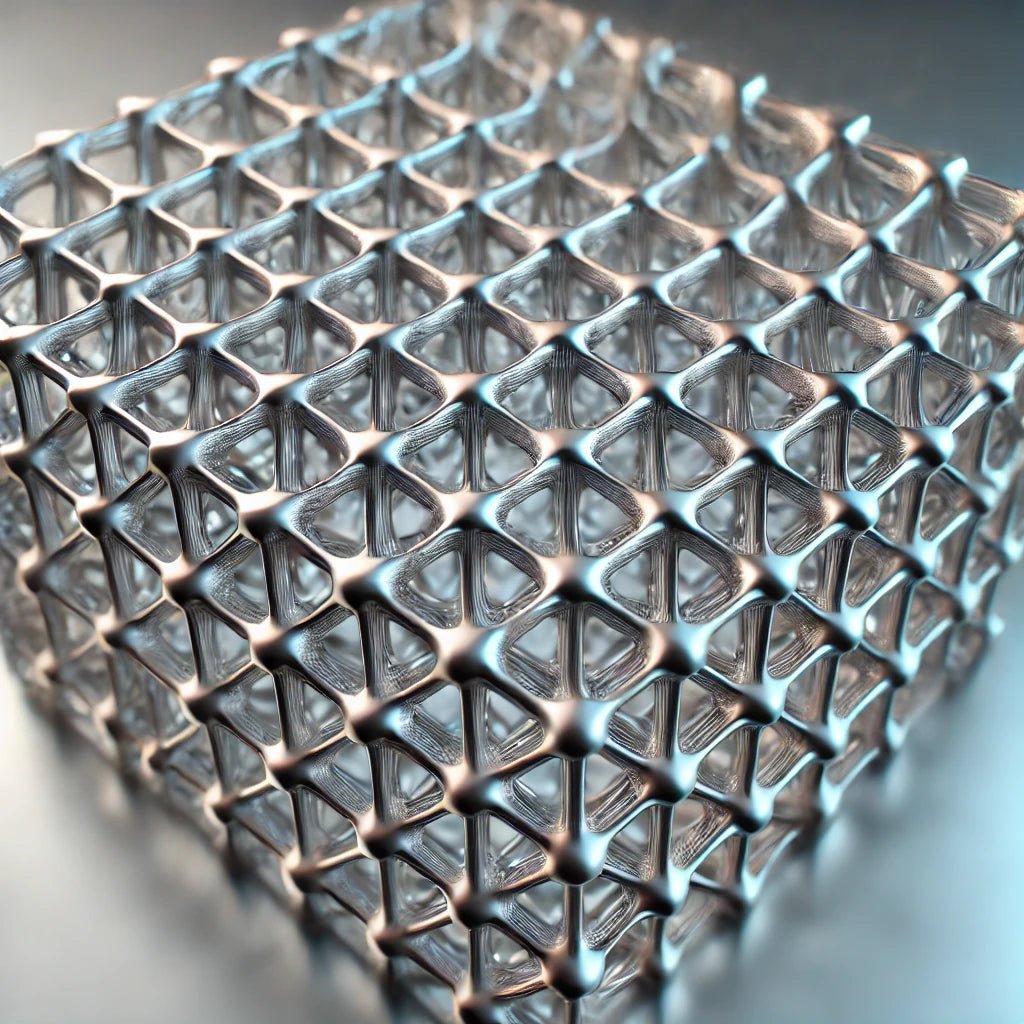

Metamaterials are artificial structures that derive their unique properties from their carefully designed internal geometries rather than their chemical composition. This allows for the creation of materials with tailored electromagnetic, acoustic, and mechanical properties, enabling functionalities that were previously unattainable.

#### Applications of Metamaterials

1. **Aerospace:**

- **Lightweight Structures:** Metamaterials allow for the design of lightweight yet strong components, crucial for aerospace applications where weight reduction is critical.

- **Radar Absorption:** Engineered surfaces that can absorb radar waves, improving stealth capabilities of aircraft.

2. **Medical Devices:**

- **Implants and Prosthetics:** Custom-designed metamaterials can be used to create implants and prosthetics that mimic the mechanical properties of human tissue, improving compatibility and comfort.

- **Diagnostic Tools:** Enhanced imaging capabilities through materials designed to interact optimally with specific wavelengths of light.

3. **Automotive:**

- **Noise Reduction:** Acoustic metamaterials can be used to design car parts that reduce noise, enhancing passenger comfort.

- **Thermal Management:** Improved heat dissipation in engine components, leading to better performance and longevity.

4. **Electronics:**

- **Electromagnetic Interference Shielding:** Metamaterials can be used to shield sensitive electronic components from electromagnetic interference, improving reliability.

- **Advanced Antennas:** Smaller, more efficient antennas for wireless communication devices.

#### Advantages of Metamaterials in Manufacturing

1. **Design Flexibility:**

- The unique properties of metamaterials allow for greater design freedom, enabling the creation of complex shapes and structures that traditional materials cannot achieve.

2. **Performance Enhancement:**

- Metamaterials can significantly enhance the performance of products by providing superior mechanical, thermal, and acoustic properties.

3. **Cost Efficiency:**

- Although the initial design and fabrication of metamaterials can be complex, they often result in cost savings in the long run through improved performance and durability.

#### Partnering with Technast for Metamaterials Solutions

At Technast, we are at the forefront of leveraging metamaterials to deliver cutting-edge solutions. Our team of experts collaborates with clients to understand their specific needs and develop customized metamaterial designs that optimize performance and functionality.

Whether you’re looking to enhance an existing product or develop a new, innovative solution, we have the expertise and technology to help you achieve your goals. From concept to production, we ensure that every step of the process meets the highest standards of quality and precision.

### Conclusion

Metamaterials are revolutionizing manufacturing by enabling the creation of structures with unprecedented properties. At Technast, we are committed to harnessing the potential of these materials to drive innovation and deliver superior solutions to our clients. Explore the future of manufacturing with us and discover how metamaterials can transform your products and processes.