Accelerating Tooling Design with Additive Manufacturing

Share

In the fast-paced world of manufacturing, the ability to rapidly prototype and produce custom tools can significantly enhance efficiency and reduce costs. Additive Manufacturing (AM), particularly through advanced technologies like those developed by Hyperganic, is revolutionizing the way tooling design and fabrication are approached.

#### The Power of Additive Manufacturing in Tooling Design

Additive Manufacturing allows for the creation of complex, highly customized tools that traditional manufacturing methods cannot easily produce. This capability opens up new possibilities for optimizing tool performance and extending tool life.

1. **Enhanced Design Flexibility**:

- **Complex Geometries**: AM enables the creation of intricate geometries and internal structures that are impossible to achieve with conventional methods. This flexibility allows for more efficient designs that can improve the performance and lifespan of the tools.

- **Custom Solutions**: Tools can be tailored to specific applications, providing bespoke solutions that meet unique manufacturing needs.

2. **Reduced Lead Times**:

- **Rapid Prototyping**: AM significantly cuts down the time required to produce prototypes. What traditionally took weeks or months can now be achieved in days, speeding up the entire design-to-production cycle.

- **On-Demand Manufacturing**: Tools can be produced on demand, reducing the need for large inventories and enabling just-in-time production.

3. **Cost Efficiency**:

- **Material Savings**: AM processes often use less material than traditional subtractive methods, reducing waste and cost.

- **Tool Longevity**: Enhanced designs and optimized materials can extend the lifespan of tools, leading to fewer replacements and lower long-term costs.

#### Hyperganic's Advanced Solutions

Hyperganic is at the forefront of integrating AM into tooling design. Their solutions leverage cutting-edge advancements in simulation and geometry representation to optimize the manufacturing process.

- **Algorithmic Design**: This approach uses algorithms to generate complex designs that are optimized for performance and manufacturability.

- **Lattice Structures**: Incorporating lattice structures into tools can reduce weight while maintaining strength and durability.

- **Topological Optimization**: This method ensures that material is used efficiently, placing it only where it is needed for optimal performance.

Hyperganic's solutions also emphasize the importance of integrating thermal management and lightweighting technologies, further enhancing the functionality and efficiency of the tools produced.

#### Case Studies

Several case studies highlight the impact of Hyperganic's solutions:

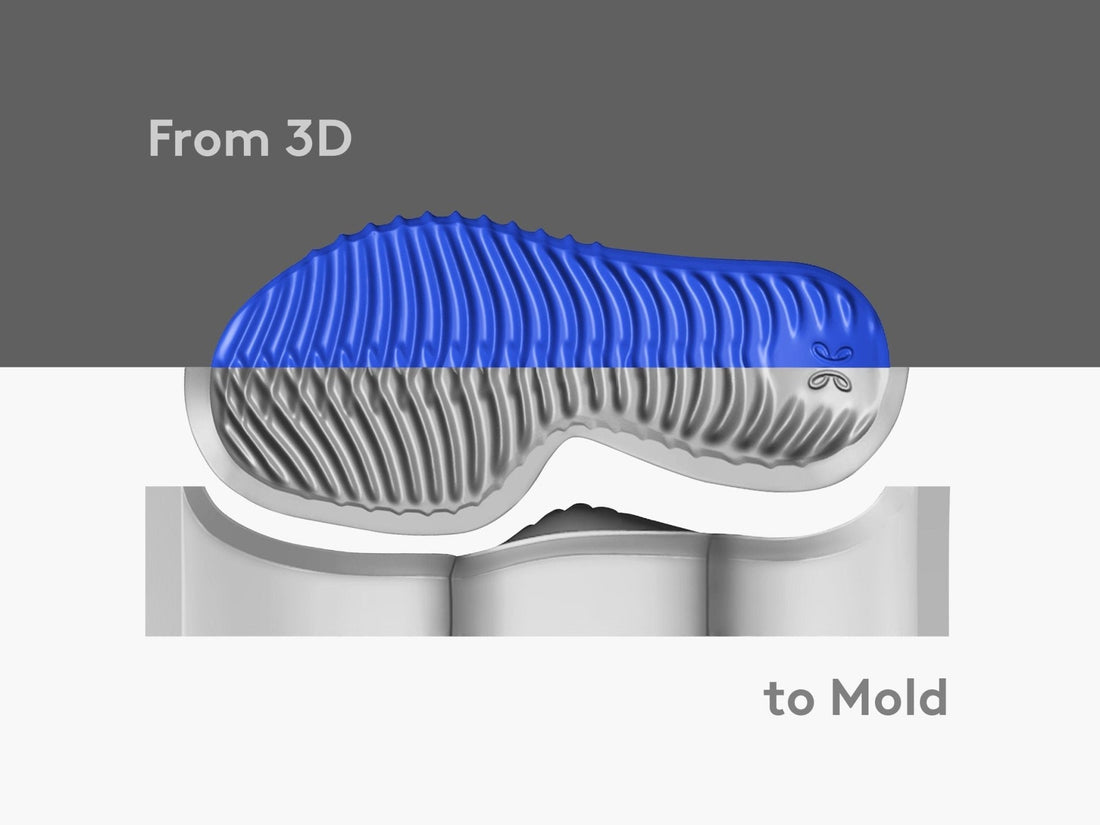

- **Footwear Production**: An 80% reduction in design-to-production time was achieved through the integration of AM in tooling design for footwear.

- **Automotive Components**: Custom tools optimized for automotive applications have demonstrated significant improvements in performance and durability.

#### Conclusion

Additive Manufacturing, with its ability to produce highly customized and efficient tools, is transforming the tooling design landscape. Companies like Hyperganic are leading the way, providing innovative solutions that enhance productivity and reduce costs. By embracing these technologies, manufacturers can stay ahead of the curve and achieve new levels of operational excellence.

#### The Power of Additive Manufacturing in Tooling Design

Additive Manufacturing allows for the creation of complex, highly customized tools that traditional manufacturing methods cannot easily produce. This capability opens up new possibilities for optimizing tool performance and extending tool life.

1. **Enhanced Design Flexibility**:

- **Complex Geometries**: AM enables the creation of intricate geometries and internal structures that are impossible to achieve with conventional methods. This flexibility allows for more efficient designs that can improve the performance and lifespan of the tools.

- **Custom Solutions**: Tools can be tailored to specific applications, providing bespoke solutions that meet unique manufacturing needs.

2. **Reduced Lead Times**:

- **Rapid Prototyping**: AM significantly cuts down the time required to produce prototypes. What traditionally took weeks or months can now be achieved in days, speeding up the entire design-to-production cycle.

- **On-Demand Manufacturing**: Tools can be produced on demand, reducing the need for large inventories and enabling just-in-time production.

3. **Cost Efficiency**:

- **Material Savings**: AM processes often use less material than traditional subtractive methods, reducing waste and cost.

- **Tool Longevity**: Enhanced designs and optimized materials can extend the lifespan of tools, leading to fewer replacements and lower long-term costs.

#### Hyperganic's Advanced Solutions

Hyperganic is at the forefront of integrating AM into tooling design. Their solutions leverage cutting-edge advancements in simulation and geometry representation to optimize the manufacturing process.

- **Algorithmic Design**: This approach uses algorithms to generate complex designs that are optimized for performance and manufacturability.

- **Lattice Structures**: Incorporating lattice structures into tools can reduce weight while maintaining strength and durability.

- **Topological Optimization**: This method ensures that material is used efficiently, placing it only where it is needed for optimal performance.

Hyperganic's solutions also emphasize the importance of integrating thermal management and lightweighting technologies, further enhancing the functionality and efficiency of the tools produced.

#### Case Studies

Several case studies highlight the impact of Hyperganic's solutions:

- **Footwear Production**: An 80% reduction in design-to-production time was achieved through the integration of AM in tooling design for footwear.

- **Automotive Components**: Custom tools optimized for automotive applications have demonstrated significant improvements in performance and durability.

#### Conclusion

Additive Manufacturing, with its ability to produce highly customized and efficient tools, is transforming the tooling design landscape. Companies like Hyperganic are leading the way, providing innovative solutions that enhance productivity and reduce costs. By embracing these technologies, manufacturers can stay ahead of the curve and achieve new levels of operational excellence.